3D Printing/Slic3r

Jump to navigation

Jump to search

Slic3r

Help

Slic3r Manual - Simple Mode - http://manual.slic3r.org/simple-mode/simple-mode

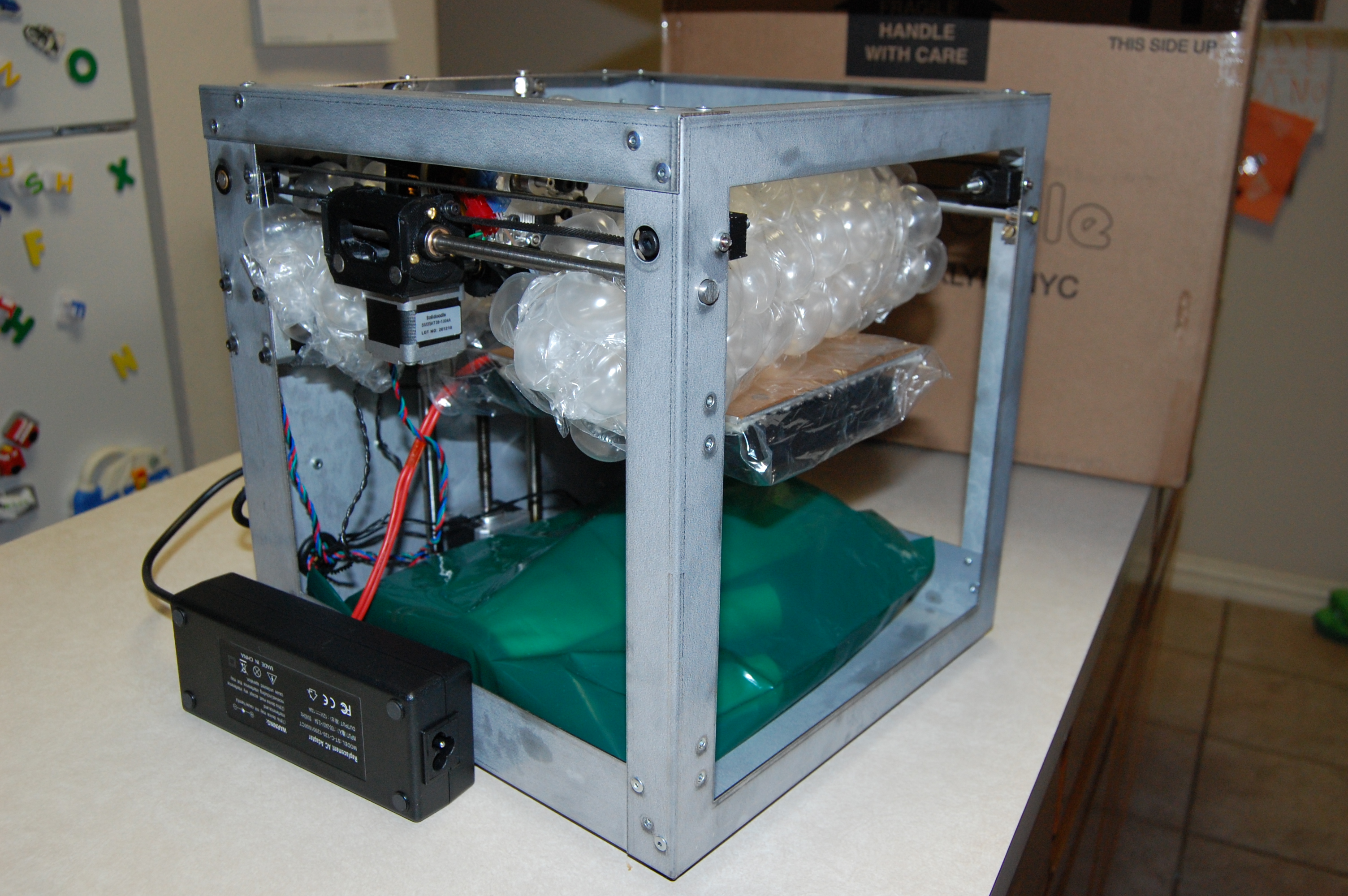

Solidoodle 3

http://wiki.solidoodle.com/slic3r-settings-sd-3

bed_size 200,200 gcode_flavor reprap print_center 100,100 use_relative_e_distances 0 vibration_limit 0 z_offset 0

Slic3r Wizard:

G-code flavor: RepRap Shape: Rectangular Size: 200 x 200 mm Origin: 0 x 0 mm Nozzle diameter: 0.5 mm Filament Diameter: 3 mm Extrusion Temperature: 200 C Bed Temperature: 70 C

Extrusion Temperature:

- Temperature needed for extruing your filament. A rule of thumb is 160 to 230 C for PLA, and 215 to 250 C for ABS

Bed Temperature:

- Bed temperature needed for getting your filament to stick to your heated bed. A rule of thumb is 60 C for PLA and 110 C for ABS.

Slic3r Settings:

Print Settings:

- Infill:

- Fill pattern: Concentric (from rectilinear)

- Only infill where needed [x] (from [])

- Skirt and Brim:

- Distance from object: 10 mm (from 6)

- Brim width: 4 mm (from 0)

- Speed:

- perimeters: 60 mm/s (from 30)

- small perimeters: 15 mm/s (30)

- external perimeters: 50% (70)

- infill: 80 mm/s (60)

- solid infill: 20 mm/s (60)

- top solid infill: 15 mm/s (50)

Filament Settings:

- Filament:

- Color: yellow

- Diameter: 1.75

- Extrusion multiplier: .7

- Extruder Temperature:

- First: 200 / other: 191

- Bed Temperature:

- First: 80 / other: 75

Printer Settings:

- General:

- Nozzel diameter: 0.4 mm (from 0.5)

- Custom Start G-Code:

;; start code G21 ; set to mm G91 ; relative position G1 Z15 F4800 ; linear move to z 15 with 4800 feed rate G90 ; set to absolute positioning G28 ; move to home M104 S197 ; set temp to 197 (ignored) M190 S81 ; set bed temperature and wait M109 S198 ; sets temp to 200 and wait (ignored) ;; start code

- Custom End G-Code:

;; end code G91 ; relative position G1 Z50 F4800 ; linear move to z 15 with 4800 feed rate G90 ; set to absolute positioning G28 X0 Y0 ; move to home on x and y axis M84 ; stop idle hold ;; end code

-

- Original Custom 1 Start G-Code:

G21 G91 G1 Z15 F4800 G90 G28

- Custom End 1 G-Code:

G91 G1 Z50 F4800 G90 G28 X0 Y0 M84

- Original Custom 2 Start G-Code:

G28 ; home all axes G1 Z5 F5000 ; lift nozzle

- Custom End 2 G-Code:

M104 S0 ; turn off temperature G28 X0 ; home X axis M84 ; disable motors

Soliprint uses default:

ABS: 215 C and 105 C bed

PLA: 190 C and 50 C bed

I bump my PLA up to 195 C and 70 C bed